I want to take you to an alternative world, one where our homes, clothes and furnishings and the food we eat is grown from mushrooms. Specifically from mycelium, the root structure of fungi, that could become an essential material used in sustainable construction to vegetarian bacon.

As part of an experimental side project I’m playing with plant roots to form a textile-like material. The aim is to produce a structurally sound material that can be used in sculptures.

A deep dive into the science is pointing to the number of entrepreneurial projects underway looking at turning agricultural waste into walls and insulation, hemp into compostable packaging, and fungal threads into luxury brand leather.

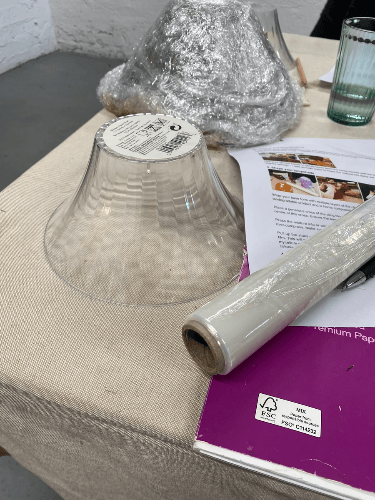

So when an opportunity to undertake a workshop to use mycelium and create a lampshade I was excited about what I was about to learn.

Delivered by Aliet Bior from Umbrellus we were patiently guided through designing and growing our own sculptural lampshade using mycelium—the living root structure of mushrooms.

Umbrellus is utilising agricultural waste and mycelium technology to drive innovation and sustainable design. They are also exploring using mycelium as a means to help workshop participants experience a different and creative experience, crafting a lampshade.

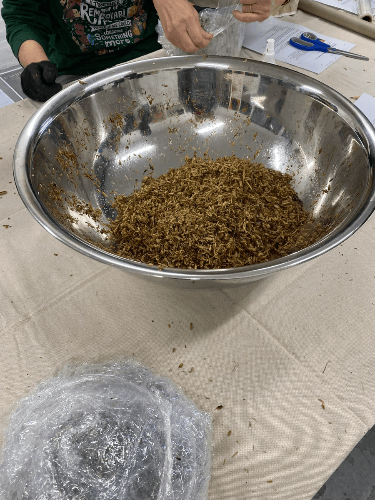

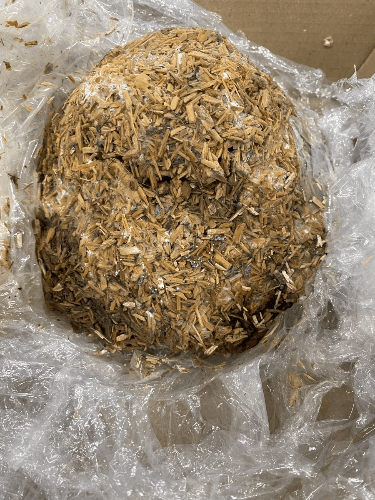

Our workshop started by utilising a pre-prepared wet mixture of hemp and mycelium spores. These were then moulded into a bowl-like shape and covered with an eco-friendly wrap, that would be left for 3 weeks to enable the mycelium to grow.

During this period we can see the mycelium, the vegetative part of the fungus, spread a network of tiny thread like structures through the hemp. It is the essential root system of the fungus, absorbing nutrients and water to support the growth of the visible mushroom body. The hemp is a fibre that creates the basis for the mycelium to grown through.

To enable the lampshade base to form, we took this home and stored it in a dark, dry, warm spot. The mycelium slowly spread, and was visible as a soft white material that started to take shape.

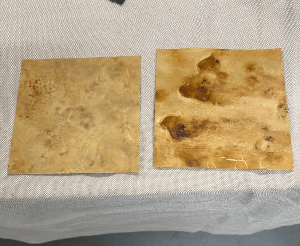

But it’s not a straightforward process without errors and in this case the first batch of mycelium and hemp was contaminated. I was unaware of this until workshop 2 and saw the mold had grown across large sections of the structure. It also showed how the mycelium had attempted to grow over the mold. Once it was clear that the mold was winning, I decided to start again. The contaminated mixture was not wasted and ended up in the compost bin.

The green indicates the mold

The next lampshade is underway and after a week the white mycelium is already growing.

Once the lampshade base is covered, the mycelium base will be removed and baked to deactivate the mycelium and solidify the base shape. Then the next creative part can start and the lamp can begin to take shape.

I’m looking forward to adding this to the many lamps I’ve created using post-consumer materials. This lampshade made from mycelium is a story of growth, patience and creativity.

A participants successful lampshade

Some participants made mushroom coasters

Aliet is exploring making 'leather -like' mycelium fabric

A unique shape

Six weeks later, cooked at 50 C over 3 hours ....my creation

Consider the possibilities